CONTROLS

display | Master 4

The Display Master4 is a microprocessor-based engine/generator controller for monitoring and control of diesel or gas powered engine-generator sets. It provides a complete array of operational, protection, automation and display features for automatically controlling and monitoring an engine/generator set. All standard and optional features of the Display Master4 are configurable from the front panel keypad and LCD display and are security password protected. The 2 row 16 character LCD display screen prompts are in plain English, providing a user-friendly operator interface. The solid-state microprocessor design provides high accuracy for all voltage monitoring, current monitoring and timing functions as well as providing many standard features which are normally only available with expensive add-on equipment.

Features

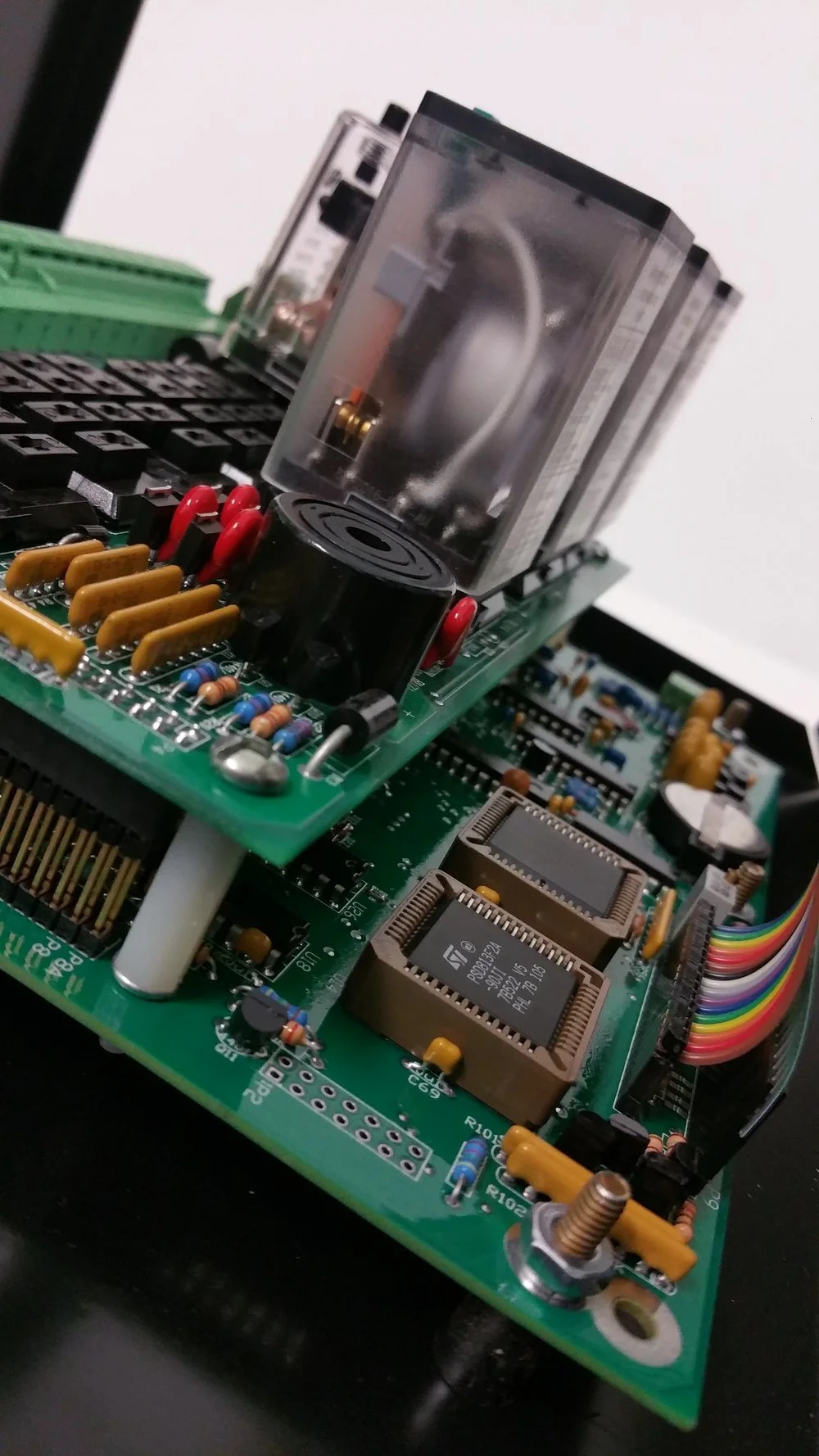

CONTROLLER

Rugged solid state microprocessor design

16 character, 2 line backlit LCD display

Easy keypad programming of all set points, password protected for security

Remote start/stop capability

System lock feature disables starting of generator for maintainance purposes (requires password to unlock)

CONTROL KEYPAD

Accurate digital readout of AC volts, amps, phase, frequency, kW, kVA, power factor, battery volts, runtime hours, oil pressure and water temperature

Indicator lights for normal operation, pre-alarm and fault conditions

Indicator light for remote start signal

All shutdowns display on screen until system is reset

CONTROL BOARD

Audible alarm for shutdowns and/or pre-alarms

6 user configurable dry contact relay outputs (plug in sockets for readily available relays)

8 user configurable digital inputs

Plug-in terminal connectors for easy curcuit board replacement

PRE ALARMS

Low engine temp

Over/Under speed

High Engine temp

Mag pickup failure

Low oil pressure

Unit NOT IN AUTO

Low oil level

Fuel/Crank Fuse

High intake air temperature

Low fuel level

Oil pressure sender fail

Low coolant level

High/Low battery volts

Charger failure

Over/under voltage

Over-current

Fuel tank leak

Oil/temp sender fail

High/Low gas pressure

High room temp

Relay failures

Service engine

High room temperature

Comms failure

SHUTDOWNS

High engine temp

Over speed

Low oil pressure

Over crank

Low fuel level

Under speed

Low coolant level

No speed signal

High oil temp

Emergency stop

Low battery

Weak battery

Fuel/Crank fuse

Fuel/Crank relay failure

Under/Over voltage

Over-current

High exhaust temp

High intake air temp

Shutter vent failed

Ground fault

Low gas pressure

High gas pressure

SPECIFICATIONS

| Enclosure | Powder coated 16 ga steel |

| DC Power Supply | 12 or 24VDC (8 to 40VDC) |

| AC Voltage Inputs | Rated (LN-N/LN-LN): 346/600Vac Configurable: 120/240/480/600Vac |

| Configurations | Wye, Delta, Offset Delta |

| Frequency | 50/60Hz (10 to 90Hz) |

| High Impedance Inputs | AC line input resistance: 3Mohm |

| Current Transformer Inputs | Rated (per line) 5A |

| Digital Inputs | Contact to Ground (12V max) |

| Relay Outputs | 16A 277Vac/30Vdc 30A 277Vac/30Vdc |

| Analog Inputs | 7V bias, 12 bit resolution |

| Ambient temperature (operating) | -20° to 85°C |

| Ambient temperature (storage) | -40° to 95°C |

| Ambient humidity | 90% non-condensing |

| Dimensions | 15lbs |

| Listings / Approvals | CSA 22.2, UL508, UL2200 |